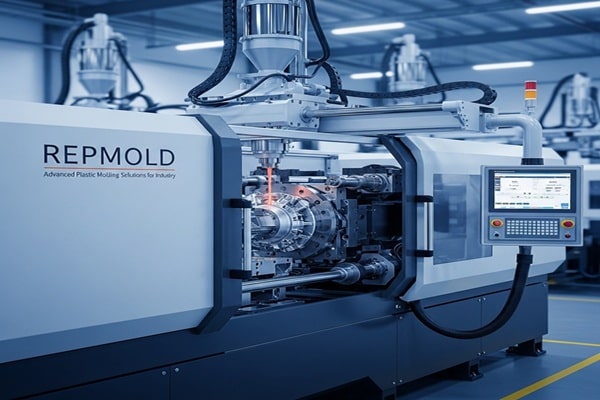

If there’s one thing modern industries agree on, it’s that speed and precision are everything. From automotive design to healthcare devices, businesses are constantly searching for ways to cut costs, enhance product quality, and accelerate production timelines. And that’s exactly where RepMold steps in — a cutting-edge innovation that’s changing how we think about plastic molding.

RepMold blends rapid prototyping with traditional molding techniques, creating a hybrid process that delivers both speed and accuracy. Whether you’re in manufacturing, engineering, or product design, understanding how RepMold works could unlock new levels of creativity and efficiency for your business.

Let’s break down why RepMold is being hailed as the future of advanced plastic molding solutions — and how it’s reshaping the industrial landscape.

What Exactly Is RepMold?

At its core, RepMold is an innovative approach to manufacturing plastic components. It takes the best of rapid prototyping — quick design testing and iteration — and merges it with the precision and scalability of traditional molding.

In simpler terms, think of RepMold as the perfect blend between speed and craftsmanship. Engineers can create detailed prototypes in record time, tweak designs instantly, and then mass-produce them using high-quality molding techniques — all without the long wait times or sky-high costs typically associated with custom manufacturing.

This means products can move from concept to reality faster than ever before, all while maintaining consistency and durability.

How the Term “RepMold” Evolved

The word RepMold didn’t just appear overnight. It’s the result of years of evolution in manufacturing innovation.

Originally, it referred to the merging of “rapid prototyping” (Rep) and “molding” (Mold). Over time, the concept expanded beyond just a technique — it became a philosophy of adaptive manufacturing, emphasizing agility, precision, and continuous improvement.

Today, RepMold represents a shift in mindset:

-

Moving away from rigid, slow processes.

-

Embracing flexibility and real-time design evolution.

-

Integrating smart technology to stay ahead of market demands.

It’s no longer just a process — it’s a symbol of modern industrial transformation.

The Core Concept: Speed Meets Stability

The beauty of RepMold lies in its balance. On one side, you have rapid prototyping, which allows teams to experiment, test, and visualize ideas quickly. On the other, you have traditional molding, which provides the strength and reliability needed for full-scale production.

By combining both, RepMold bridges the gap between innovation and implementation.

Here’s what that looks like in practice:

-

Rapid prototyping accelerates the design process. Teams can produce and test physical models within days instead of weeks.

-

Traditional molding ensures that once the design is finalized, it can be reproduced flawlessly — whether it’s one unit or one million.

This seamless integration reduces turnaround time dramatically while maintaining the highest quality standards.

Key Features and Benefits of RepMold

So, what makes RepMold so special? A lot, actually. Here are some of the standout advantages that are making waves across multiple industries:

1. Lightning-Fast Production

RepMold drastically shortens product development cycles. Companies can go from concept to prototype in a fraction of the time it once took — meaning faster launches and more competitive products.

2. Incredible Flexibility

Because RepMold works with various materials and complex designs, it’s ideal for industries with ever-changing needs. Whether it’s a car part, a medical tool, or a piece of consumer tech, RepMold adapts with ease.

3. Cost Efficiency

Traditional manufacturing can be expensive due to tooling and setup costs. RepMold minimizes waste, reduces the need for multiple mold iterations, and cuts material expenses — all while delivering top-tier quality.

4. Consistent Precision

Even with rapid turnaround times, precision never takes a back seat. RepMold delivers uniform quality across every batch, ensuring products meet exact specifications every time.

5. Collaborative Innovation

RepMold encourages closer collaboration between designers, engineers, and manufacturers. This unified approach reduces communication gaps and leads to smarter, more innovative designs.

How RepMold Works: Step-by-Step Process

Curious about how this technology actually operates? Here’s a quick breakdown of the RepMold process from start to finish:

-

Digital Design: Engineers begin by creating detailed 3D models using CAD software. This digital foundation allows for pinpoint accuracy in every detail.

-

Rapid Prototyping: The design is turned into a physical prototype — quickly. This lets teams test performance, ergonomics, and appearance before full-scale production.

-

Feedback and Refinement: Adjustments are made instantly based on test results or customer feedback.

-

Final Molding: Once the prototype is perfected, production begins using traditional molding techniques with advanced materials.

-

Quality Control: Every batch undergoes rigorous testing to ensure consistency, durability, and precision.

This streamlined workflow makes RepMold faster, more flexible, and more reliable than conventional methods.

Applications Across Industries

The versatility of RepMold is one of its biggest strengths. It’s already making a major impact in a variety of sectors:

Automotive

Car manufacturers use RepMold to create complex, lightweight components quickly. It reduces lead times for prototypes and supports the production of more fuel-efficient designs.

Healthcare

RepMold’s precision and customization capabilities make it ideal for medical devices and implants. Doctors and engineers can collaborate to design patient-specific solutions faster.

Consumer Electronics

From sleek smartphone casings to ergonomic accessories, RepMold ensures every design detail is both functional and visually appealing.

Aerospace

The technology supports lightweight yet strong materials essential for aviation. It helps reduce fuel consumption while maintaining strict safety standards.

Consumer Goods

RepMold gives brands the agility to test new product ideas quickly, adjust designs based on market response, and deliver fresh innovations faster than ever.

Sustainability and Waste Reduction

One of the most impressive things about RepMold is its contribution to sustainable manufacturing. Traditional production methods often waste materials during testing and tooling. RepMold changes that.

-

Less waste: Prototyping uses just the amount of material needed.

-

Smarter resource use: Each stage of production is optimized for efficiency.

-

Reduced energy consumption: Faster cycles and fewer remakes mean lower overall energy use.

By focusing on efficiency and environmental responsibility, RepMold proves that modern manufacturing can be both innovative and eco-conscious.

Also Read : ovppyo What It Means and Why It’s Trending

The Future of RepMold: Smart Tech Meets Manufacturing

RepMold is just getting started. The next generation of this technology is integrating smart tooling, AI-driven analytics, and predictive maintenance.

Here’s what’s on the horizon:

-

Smart Tooling: Future molds will adjust automatically to maintain optimal performance and reduce human error.

-

AI Integration: Artificial intelligence will analyze production data in real-time, spotting inefficiencies before they become costly problems.

-

Predictive Maintenance: Sensors will monitor equipment health, alerting manufacturers before breakdowns occur — minimizing downtime and boosting productivity.

These advancements are paving the way for a new era of intelligent, self-optimizing factories — and RepMold is right at the heart of it.

Why RepMold Is the Future of Manufacturing

In today’s competitive world, being fast isn’t enough — you also need to be smart, adaptable, and sustainable. That’s exactly what RepMold delivers.

By combining rapid prototyping with proven molding techniques, RepMold enables companies to:

-

Launch products faster

-

Maintain exceptional quality

-

Cut production costs

-

Minimize waste

-

Stay ahead of competitors

It’s not just a process; it’s a revolution. As technology continues to advance, RepMold will only grow more powerful — shaping how industries design, build, and innovate for decades to come.

Final Thoughts

Whether you’re a manufacturer, engineer, or product designer, embracing RepMold could be the key to future-proofing your business. It’s fast, flexible, and remarkably precise — exactly what modern industry needs.

Innovation isn’t just about doing something new; it’s about doing it better, smarter, and more sustainably. And that’s the promise of RepMold — a truly transformative leap in how we bring ideas to life.